600KN Capacity Servo Hydraulic Testing Machine with Closed Loop Control for Stress and Strain Rate

600KN Capacity Servo Hydraulic Testing Machine with Closed Loop Control for Stress and Strain Rate

Application

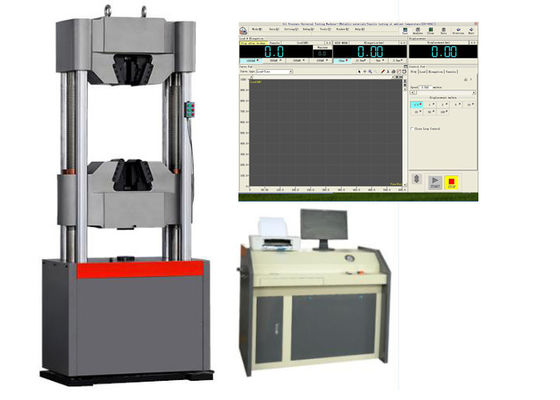

1. Main Machine Structure

The main machine adopts a four-column, two-lead-screw structure integrated with a hydraulic cylinder. The tension testing space is located at the upper section of the main machine, while the compression and bending testing spaces are positioned between the lower crosshead and the worktable--ensuring rational space allocation for diverse metal material tests.

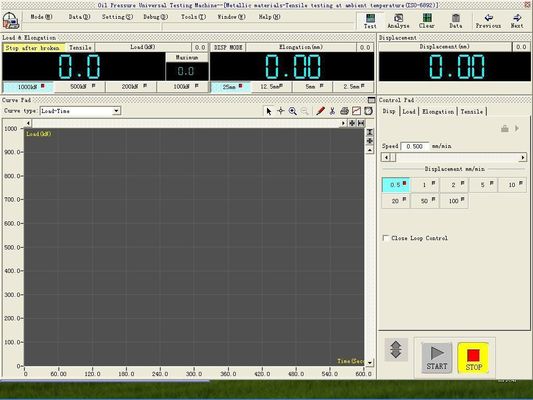

2. Measurement & Control System

Equipped with a digital multi-channel closed-loop control system, the instrument features three core closed-loop control functions, supporting independent closed-loop control modes for stress, strain, and displacement. It also enables smooth impact switching between control modes, with its stress rate and strain rate fully complying with the requirements of national and international metal tensile test standards, such as GB/T228.1-2010.

This advanced control system ensures high-precision, stable test processes, delivering reliable and traceable data for material mechanical property evaluation.

Price advantage

We have significantly enhanced our independent R&D capabilities and established an in-house machining center, enabling us to achieve independent manufacturing of core components. This vertical integration strategy allows us to realize supply chain cost optimization without compromising product quality--a key competitive edge rooted in our manufacturing expertise.

Compared with low-cost, inferior-quality alternatives on the market, our high-performance testing instruments deliver far greater long-term cost savings for customers. By minimizing equipment failure rates, we not only reduce your maintenance and repair costs but also boost the machine's operational efficiency--ensuring uninterrupted testing workflows and higher productivity.

This exceptional cost-performance ratio translates into tangible, sustainable benefits for our customers, perfectly balancing reliable quality, reduced total cost of ownership (TCO), and improved operational efficiency.

Meet Standards

ISO 6934 BS4449, ASTM C39, ASTM A370, ASTM E4, ASTM E8, ASTME9, ASTMA615, ISO6892, ISO7438, ISO7500-1, ISO 15630 EN10002-4, GB/T228-2002, GB 16491-2008, HGT3844-2008 QBT 11130-1991, HGT 3849- 2008,GB6349-1986, ASTM C165, EN826, EN1606, EN1607, EN12430 etc.

Main technical parameters

| Model |

WAW-600D |

| Max. test force(kN) |

600KN |

| Structure |

Four columns two ball screws, oil cylinder down-setting type |

| Load range |

2%-100% |

| Middle Beam elevating speed (mm/min) |

170 mm/min |

| Max. Tensile space (mm) |

750mm |

| Max. Compression space (mm) |

650mm |

| Piston stroke(mm) |

200mm |

| Stranded wire clamping range |

Φ13-40mm |

| Flat sample clamping range |

0-15mm |

| Power total |

2.5KW |

| Compression plate size |

Φ180mm |

| Bending support roller distance |

300mm |

Frequently Asked Questions:

Q1: How can I select the most suitable testing instrument?

A1: Our professional technical team will provide tailored optimal recommendations once you share your specific test requirements (e.g., test type, material to be tested) and technical specifications (e.g., load range, temperature range, accuracy standards, compliance with international/national standards like ISO, ASTM, GB). We analyze your actual application scenarios to ensure the recommended product fully matches your testing needs and long-term operational goals.

Q2: Do you offer customization services?

A2: Yes, we provide comprehensive customization services. In addition to our standard product lineup, we can develop customized solutions tailored to your specific requirements--such as modified technical parameters (e.g., extended temperature/load range), specialized fixtures for unique samples, custom software functions (e.g., data analysis modules), or integrated test workflows. Please feel free to share your detailed needs, and our R&D and engineering teams will strive to deliver solutions that align with your operational demands.

Q3: What packaging do you use for the machines, and is the equipment safely protected during transportation?

A3: All our testing instruments are packaged in export-grade wooden crates compliant with international shipping standards (e.g., ISPM 15)--ensuring robust structural protection against impacts, vibrations, and handling risks. Inside the crate, the machine is wrapped in moisture-proof film and cushioned with high-density shock-absorbing foam to prevent humidity damage and mechanical wear.

يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!  يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!